Robots as Guardians: How Automation Has Made Chinese Workplaces Safer

Industrial robots are often discussed primarily in terms of their employment effects. New evidence from China shows that automation has also delivered substantial improvements in workplace safety, with sharp reductions in accidents and fatalities.

“Life is paramount; safety comes first” (生命至上,安全第一) is a common slogan in Chinese factories. Workplace accidents and fatalities were an important concern during China’s manufacturing boom. Over the past decade, however, workplace safety has improved dramatically. We argue that a key yet underappreciated driver of this improvement is the rise of industrial robots. By taking over the most dangerous tasks on factory floors, robots can help safeguard worker safety.

Much of the public debate about automation focuses on job displacement and wages. While these concerns are real, they overlook an equally important dimension: the physical risks associated with production. In China, where hazardous production has long been concentrated, this margin is particularly salient.

China’s robot adoption and declining workplace accidents

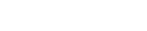

Figure 1 uses data from the International Federation of Robotics to document the expansion of industrial robot use in China. The national stock of robots rose from 127,193 units in 2013 to 756,527 in 2019, an increase of nearly 500%. Over the same period, workplace safety outcomes showed marked improvement. The number of serious workplace accidents per thousand population declined from 0.218 in 2013 to 0.040 in 2019, while the fatality rate fell from 0.0446 to 0.0218.

Figure 1. Changes in Robot Exposure and Workplace Safety

Note: This figure plots the annual number of accidents and fatalities per thousand population (left axis) and the total number of robots in millions (right axis) from 2013 to 2019. Data sources: International Federation of Robotics and local municipal statistical bulletins.

Measuring robot exposure across Chinese cities

To identify the causal impact of robots on workplace safety, we construct a city-level measure of robot exposure. Cities are considered more exposed to industrial robots if, in the baseline year, a larger share of their workforce was employed in industries that subsequently became more robot-intensive (i.e., had higher robots-per-worker at the industry level)—for example, automobile and electronics manufacturing. In contrast, cities with baseline employment concentrated in industries that remained less robot-intensive, such as furniture production or construction, are considered less exposed. We then relate this measure of robot exposure to workplace safety outcomes in our empirical analysis.

Measures of workplace safety

Workplace safety is difficult to measure in China, where government officials have incentives to manipulate reporting. To address this challenge, we combine three independent outcome measures, each with distinct strengths and limitations. This measurement strategy constitutes a key contribution to our study.

First, we use official city-level statistics on severe workplace accidents and fatalities, collected from municipal statistical bulletins. In our baseline estimates, we find that an increase of one robot per thousand workers is associated with a reduction of approximately 0.25 workplace accidents and 0.035 fatalities per thousand population. We calculate that the rise in robot adoption between 2013 and 2019 accounts for roughly two-thirds of the observed decline in accidents and over 70% of the reduction in fatalities during this period—effects that are economically large and highly statistically significant.

Second, we turn to household data from the China Health and Nutrition Survey, which captures recent injuries and work-related illnesses at the individual level. This measure allows us to move beyond fatalities and examine the everyday risks faced by workers. It also enables us to explore heterogeneous effects across workers and to decompose the city-level effect into distinct channels.

Third, we exploit Baidu Index search data, tracking queries related to workplace injury certification and compensation. These searches provide a proxy for safety incidents and legal claims, independent of official reporting.

Crucially, all three measures point to the same conclusion: greater robot exposure is consistently associated with improved workplace safety.

Who benefits most?

The safety gains from robots are not evenly distributed. Using household survey data, we find that reductions in workplace injuries are greatest among older workers, less-educated workers, and those in physically demanding factory jobs, such as technicians and skilled production workers. By contrast, we observe little effect for occupations far removed from industrial settings, including senior professionals and service workers. These patterns support the interpretation that robots primarily reduce risk by taking over the most hazardous tasks, rather than improving safety uniformly across all jobs.

Mechanisms behind the safety gains from robots

Robots can enhance workplace safety through several distinct channels. First, they may reduce accidents directly by making existing jobs safer for workers who remain in the same occupation—what we refer to as the within-occupation improvement channel. Second, they may lower risk indirectly by shifting workers into safer occupations—the reallocation channel. Third, if robot adoption reduces overall employment, exposure to workplace risk may decline simply because fewer individuals are working—this is the non-employment channel.

Using a standard decomposition framework borrowed from industry productivity literature, we express changes in workplace injuries in each city as the sum of three components and regress each component on city-level robot exposure. We find that the decline in workplace injuries associated with robot adoption is driven almost entirely by within-occupation improvement, while reallocation and non-employment play limited roles. In other words, robots reduce injuries primarily by making existing occupations safer, not by pushing workers out of employment.

Conclusion

While industrial robots are often viewed as a threat to employment and wages, our research highlights their substantial benefits for workplace safety. In China, where industrial accidents have long been a serious concern, robots have contributed to markedly safer work environments. Policymakers and business leaders should therefore consider not only the labor-market consequences of automation, but also its potential to improve worker well-being.

(Acknowledgment: We used AI tools to copyedit this article. Any remaining errors are the authors’ responsibility.)

Reference

Luo, Wei, Lixin Tang, Yaxin Yang, and Xianqiang Zou. 2025. “Robots as Guardians: Industrial Automation and Workplace Safety in China.” Journal of Development Economics 172: 103381. https://doi.org/10.1016/j.jdeveco.2024.103381.

Latest

Most Popular

- VoxChina Covid-19 Forum (Second Edition): China’s Post-Lockdown Economic Recovery VoxChina, Apr 18, 2020

- China’s Great Housing Boom Kaiji Chen, Yi Wen, Oct 11, 2017

- China’s Joint Venture Policy and the International Transfer of Technology Kun Jiang, Wolfgang Keller, Larry D. Qiu, William Ridley, Feb 06, 2019

- The Dark Side of the Chinese Fiscal Stimulus: Evidence from Local Government Debt Yi Huang, Marco Pagano, Ugo Panizza, Jun 28, 2017

- Wealth Redistribution in the Chinese Stock Market: the Role of Bubbles and Crashes Li An, Jiangze Bian, Dong Lou, Donghui Shi, Jul 01, 2020

- What Is Special about China’s Housing Boom? Edward L. Glaeser, Wei Huang, Yueran Ma, Andrei Shleifer, Jun 20, 2017

- Evaluating Risk across Chinese Housing Markets Yongheng Deng, Joseph Gyourko, Jing Wu, Aug 02, 2017

- Privatization and Productivity in China Yuyu Chen, Mitsuru Igami, Masayuki Sawada, Mo Xiao, Jan 31, 2018

- How did China Move Up the Global Value Chains? Hiau Looi Kee, Heiwai Tang, Aug 30, 2017

- China’s Shadow Banking Sector: Wealth Management Products and Issuing Banks Viral V. Acharya, Jun Qian, Zhishu Yang, Aug 09, 2017

Facebook

Facebook  Twitter

Twitter  Instagram

Instagram WeChat

WeChat  Email

Email